We primarily carry Chinese vacuum tubes and we only carry the best quality grade. There are two testing methods used on all tubes we sell.

1. GF (Grant Fidelity) Test Method

2. Factory Test Method

About GF (Grant Fidelity) Test Method:

Grant Fidelity (GF) Test Method is a unique after-production test method we use on high end tubes we sell, which includes 5 steps on 5-specs:

1) Starting before factory shipping, we stipulate our acceptable plate current tolerance to factory, which is much narrower than the factory QC pass tolerance which can swing +/- 40%.

From each production run of high end tubes, typically only a small percentage of tubes are in our stipulated specification range. Rest could vary from nominal specification up to 40% or even more. Grant Fidelity pay a sizable premium over factory quoted price as ‘selecting fee’ to secure our supply of the best quality tubes. We believe in ‘you get what you paid for’ – which is more than true when sourcing from China! We hope our customers share the same value with us to appreciate and recognize that quality does come with a price premium.

2) Once the factory rated a tube as suitable for our stipulated sourcing criteria, further testing is conducted on every tube to ensure no visible defects. Please note that the shape of glass enclosure is NOT considered a defect as this is a manual process – no two tubes will be 100% identical.

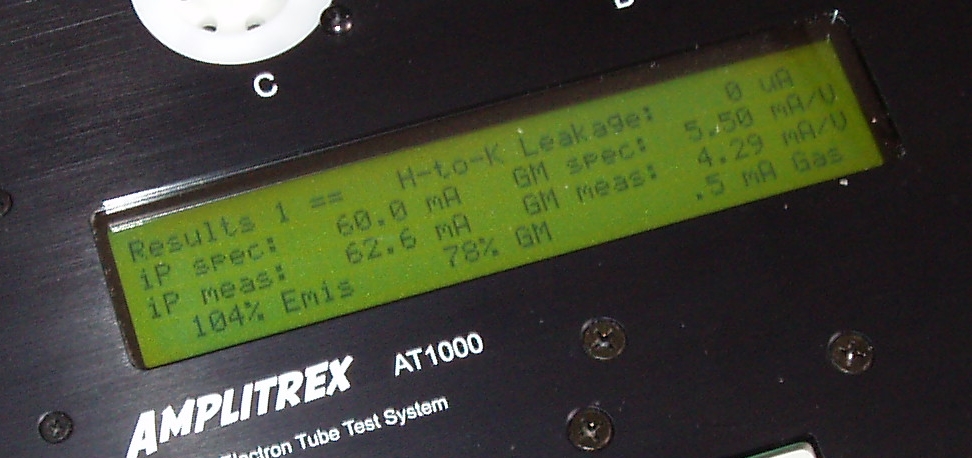

3) All tubes are then further tested on the industry’s most advanced computerized electron tube testing system – Amplitrex AT1000 tube tester in Canada, for all 5 specs: Plate current, Transconductance, Heater-to-Cathode Leakage, Internal Gas and Microphonic. Amplitrex test tubes at real working voltage except for high voltage tubes such as 845/211/805 (the maximum voltage a tester can get to is 500V). Remember factory method only tests plate current in their factory QC process; Grant Fidelity testing method tests all 5.

4) All tubes that went through the Amplitrex test are then further graded according to the 5-spec test results. Top 10% ‘Best of Best’ quality grade will be set aside for the most quality conscious buyers for a premium price.

We match power tubes plate current well within 5% – in many cases much less than 3%. This is a much closer matching than the tube factory matching method and all tubes with inferior specs on other parameters will be left in the ‘Factory QC Pass’ stockpile. Buyers can select the quality grade – ie. either ‘Top 10% Best Grade’ or ‘Factory QC Pass Grade’ as they see fit their own needs and budget, when placing order from our website product listing pages.

5) Any tubes that have FAILED any of Grant Fidelity 5-spec test in Canada will be rejected back to factory for warranty replacement. In the past decade, we have rejected thousands of tubes back to Chinese tube factories, even though they label the tubes as ‘QC pass’.

‘Top 10% Best of Best Grade’ is the best quality Grade we carry and they will last longer than an inferior grade tube. They will also perform better in a live circuit due to its superior electronic parameters. Top 10% Best Grade tubes are sold at premium price, for its quality, rarity and longevity.

About Factory Test Method

This refers to the standard production quality control method used at tube factory. If a tube is sold as factory tested by another vendor, it has NOT been tested under GF Test Method – which is proprietary, and is conducted by Grant Fidelity in Canada only.